Most people approach leak location detection as if it were a single event: you see a wet spot, you grab a tool, you start guessing. The common mistake is treating leaks as obvious and static, when in reality they are often subtle, intermittent, and influenced by pressure, temperature, and system dynamics. Another misconception is that “more technology” automatically means better results. Buying an expensive acoustic device or thermal camera without a structured process usually leads to confusion, false positives, and wasted time.

Effective leak location detection is a disciplined combination of planning, methodical inspection, and appropriate technology. It is less about heroics and more about repeatable practices. The best technicians and engineers are not just good with gadgets; they understand how water, gas, or other fluids behave in real systems, and they follow a clear sequence of steps from initial suspicion to final confirmation. When you get the fundamentals right, the tools amplify your skills instead of compensating for guesswork.

Whether you are working in residential plumbing, industrial facilities, or municipal water networks, the underlying principles are the same: verify there is a leak, narrow the search area logically, choose the right detection method for the conditions, and confirm the exact location before any invasive work begins. The following best practices will help you move from reactive “hunt and hope” to a consistent, evidence-based approach to leak location detection.

Start With Verification

The first best practice is surprisingly simple: confirm that a leak actually exists before you begin tearing things apart or deploying advanced equipment. Many hours are wasted chasing what turns out to be condensation, user error, or a temporary pressure fluctuation. In water systems, a basic meter test is often the fastest verification tool. Shut off all known fixtures and observe the meter; if it continues to move, you likely have a hidden leak. In gas systems, pressure drop tests under controlled conditions can provide similar confirmation.

Once you suspect a leak, collect as much contextual information as possible. Ask questions about when the issue was first noticed, whether it is constant or intermittent, and what changes occurred around the time it started (new appliances, renovations, seasonal shifts). This history often narrows your search area dramatically and prevents you from overlooking simple causes like faulty fixtures or overflows that mimic leaks. Proper documentation at this stage, including photos and notes, lays the groundwork for a structured investigation.

Verification also involves ruling out false positives. For example, high humidity and poor insulation can create condensation that drips and pools in ways that look like a leak. Appliances such as air conditioners, refrigeration units, and high-efficiency furnaces can produce significant condensate. Distinguishing between process-related moisture and actual line leakage is critical, and it usually requires patience, observation over time, and sometimes temporary isolation or shutdown of suspect equipment.

Use Systematic Isolation

After confirming that a leak exists, the next best practice is systematic isolation. Instead of scanning an entire building or network randomly, break the system into logical sections and test each one. In plumbing, this may mean closing zone valves, isolating hot from cold lines, or separating indoor from outdoor piping. For larger facilities or municipal systems, it might involve isolating districts, loops, or branches using existing valves and flow meters.

Isolation is powerful because it converts a large, complex problem into smaller, manageable segments. For each segment, you can perform pressure tests, flow measurements, or acoustic checks to determine whether the leak is upstream or downstream of a given point. This process of elimination dramatically reduces the area that requires detailed inspection. It also helps you prioritize high-risk sections, such as older pipes, joints, and areas with known ground movement or corrosion.

When isolating, maintain clear communication and documentation. Label which valves were closed, what tests were performed, and the results for each section. In a facility setting, coordinate with operations personnel so that production or safety systems are not inadvertently compromised. A common pitfall is changing multiple system conditions at once and then being unable to interpret the results. Change one variable at a time, record it, and move methodically; that discipline is a hallmark of effective leak location detection.

Choose The Right Detection Method

Not all leaks behave the same, and not all detection methods are suitable for every situation. One of the most important best practices is matching your technique to the type of system, the environment, and the suspected leak characteristics. Acoustic leak detection, for example, is excellent for pressurized water lines where leaks create turbulence and noise. However, it is less effective in very low-pressure systems or in environments with high background noise that masks the signal.

Thermal imaging can be highly effective for locating hot water leaks, radiant heating leaks, or leaks that cause temperature differences in building materials. But it requires training to interpret correctly, and it has limitations when temperature gradients are small or when surface conditions obscure the thermal pattern. Similarly, tracer gas methods (using hydrogen or helium) can pinpoint leaks with impressive accuracy, yet they demand careful handling, proper ventilation, and an understanding of gas diffusion and safety protocols.

For underground utilities and larger networks, correlators, ground microphones, and data loggers can help detect and triangulate leak positions over long distances. In some cases, satellite-based technologies or advanced analytics on flow and pressure data can indicate likely leak zones. Regardless of the tools, the best practice is to understand what each method is good at, what conditions it needs to work well, and how to combine multiple methods when a single approach is inconclusive.

Interpret Clues From The Environment

Technology is only part of the picture; the environment around the suspected leak often provides critical clues. Moisture stains, mold growth, efflorescence on masonry, warped flooring, or peeling paint can all indicate chronic water intrusion. The pattern and location of these signs can help you infer the probable path of water and the likely source. For gas leaks, dead vegetation above buried lines, unusual odors, or hissing sounds are key indicators that should never be ignored.

Understanding building or site construction is equally important. Leaks rarely travel in a straight line from source to visible symptom. Water tends to follow the path of least resistance, which might be along beams, conduits, insulation, or even air gaps. In multistory buildings, a ceiling stain may originate several meters away or on a different level. Reviewing as-built drawings, if available, and considering typical routing of pipes and ducts will keep you from opening the wrong areas and causing unnecessary damage.

Environmental conditions such as temperature, soil type, and groundwater levels also influence how leaks present. In clay soils, water may surface far from the actual leak due to lateral spreading, while in sandy soils it may drain vertically with minimal surfacing. Seasonal freeze-thaw cycles can create movement and stress points that correlate with leak locations. Taking time to read the environment and connect these physical clues with system layout is a core best practice that separates experienced leak locators from those who rely purely on instruments.

Minimize Invasive Work

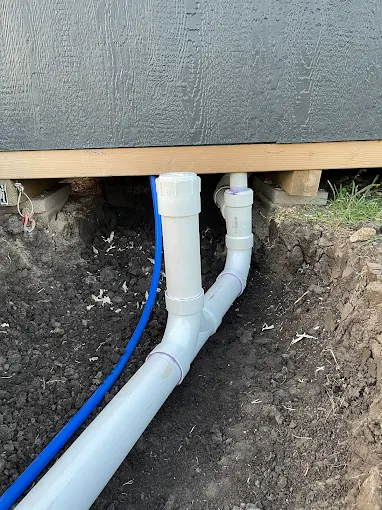

A key objective in best-practice leak location detection is to minimize destructive or invasive work. Cutting into walls, slabs, or pavements is costly and disruptive, so it should only happen after you have gathered sufficient evidence to justify the exact spot. Non-destructive testing methods, including acoustic listening, thermal imaging, moisture mapping, and tracer gas detection, should be used to narrow the target area as much as possible before any demolition begins.

When invasive work is unavoidable, plan it strategically. Choose access points that provide the greatest visibility or reach, and consider whether small exploratory openings can confirm your hypothesis before a larger repair is undertaken. In commercial or industrial settings, coordinate with stakeholders to schedule invasive work during low-impact periods and ensure that safety and containment measures are in place. Proper protection of finishes, equipment, and surrounding areas shows professionalism and reduces the overall cost of the leak investigation.

Another best practice is to document invasive steps with photos and notes, both for your own reference and for the client or facility manager. This record helps explain why a particular location was chosen and what was found once the area was opened. Over time, such documentation also becomes a valuable training resource, illustrating how different types of leaks manifested and how pre-opening indicators correlated with actual conditions.

Document, Communicate, And Learn

Leak location detection is not just a technical task; it is also a process of communication and continuous improvement. From the first suspicion to the final confirmation, keep a clear record of your observations, tests, and decisions. This includes meter readings, pressure test results, photos of symptoms, instrument screenshots, and notes on environmental conditions. When a leak is finally exposed and repaired, capture “before and after” evidence to close the loop.

Effective communication with clients, building occupants, or operations staff is essential throughout. Explain what you know, what you suspect, and what you plan to do next, in plain language. Set expectations about the possibility of multiple tests, the need for access to certain areas, and the potential for hidden conditions. When people understand the logic behind your approach, they are far more patient and cooperative, which in turn allows you to work more efficiently and safely.

Finally, treat every leak investigation as a learning opportunity. Review what went well and what could have been done differently. Did the first indication point you in the right direction, or did you overlook an early clue? Did your choice of detection method fit the situation, or would another tool have been faster or more accurate? Over time, this reflective practice builds expertise that no single device can provide. For additional reading and reference materials on leak detection methodologies, you can consult resources such as null.

Frequently Asked Questions

How do I know if I should call a professional for leak detection? If you have confirmed abnormal water or gas usage, see persistent dampness or staining with no obvious source, or detect gas odors or hissing from lines, it is wise to contact a professional. DIY checks like meter tests and visual inspection are a good starting point, but hidden leaks inside walls, slabs, or underground often require specialized tools and experience. A professional can systematically verify the presence of a leak, isolate sections of the system, and apply appropriate detection methods to avoid unnecessary damage. In safety-critical situations, such as suspected gas leaks, evacuate the area and contact emergency services or your utility immediately.

What is the most accurate method for finding a leak? There is no single “most accurate” method for every situation; accuracy depends on matching the technique to the leak type and environment. Acoustic leak detection is highly effective for many pressurized water systems, especially when background noise is controlled. Tracer gas methods can be extremely precise for both water and some gas leaks, particularly in complex or concealed systems. Thermal imaging excels in detecting hot water or heating system leaks that create temperature variations. The most reliable results often come from combining methods: for example, using isolation and pressure testing to narrow an area, then applying acoustic or tracer gas techniques to pinpoint the exact spot.

Why can leaks be so far from visible damage? Fluids follow the path of least resistance, which rarely aligns with straight lines or visible surfaces. In buildings, water may travel along pipes, beams, insulation, or vapor barriers before emerging as a stain or drip many meters away from the source. In soil, properties like permeability and layering influence how water moves, sometimes causing surface evidence at a distance from the actual leak. Gravity, capillary action, and air currents all play a role in how moisture migrates. This is why best practices emphasize understanding construction details and environmental conditions, rather than assuming the visible damage is directly below or behind the leak.

How long should a proper leak location investigation take? The duration varies widely depending on system complexity, access, and the nature of the leak. A straightforward residential leak with clear symptoms might be located within an hour or two using basic tests and tools. In contrast, a subtle leak in a large commercial facility or an extensive underground network can require multiple visits, staged tests, and coordination with operations to isolate sections safely. Rushing the process often leads to misdiagnosis and unnecessary invasive work. A well-planned, systematic investigation may take longer up front but usually results in less damage, lower repair costs, and higher confidence in the outcome.

Can regular maintenance reduce the need for complex leak detection? Yes, proactive maintenance significantly reduces both the frequency and severity of leak investigations. Routine inspections of exposed piping, valves, and joints, regular meter or flow data reviews, and scheduled pressure tests can identify issues before they become major hidden leaks. In larger systems, installing monitoring devices such as flow meters, pressure sensors, and leak detection alarms provides early warning signals. When anomalies are caught early, the affected area is usually smaller, symptoms are clearer, and simpler detection methods are often sufficient. Integrating leak awareness into your maintenance program is one of the most cost-effective best practices you can adopt.