Most homeowners misunderstand drain repair and installation in one crucial way: they think it is all about brute force and replacing pipes as soon as something goes wrong. In reality, the most successful drain repairs come from careful diagnosis, methodical planning, and understanding how the entire drainage system works together. Rushing to cut and replace pipe without understanding slope, venting, and material compatibility often creates new problems that show up months later as slow drains, sewer smells, or recurring clogs.

Another common misconception is that drain work is either “simple DIY” or “call a plumber and forget about it.” The truth sits in between. There are many tasks a careful homeowner can perform safely and effectively—such as minor trap replacement, clearing accessible clogs, or upgrading certain drain sections—but only if they approach the work like a pro: using the right tools, respecting codes, and knowing their limits. Good drain repair installation is less about being handy and more about being deliberate. When you understand how water and waste move through pipes, how slope affects flow, and why certain fittings are used in specific places, you can make smarter decisions, whether you are doing the work yourself or hiring a professional.

Finally, homeowners often overlook the long-term impact of materials and installation methods. Choosing the cheapest pipe, ignoring proper support, or using the wrong connectors can lead to leaks inside walls, floor damage, mold, and expensive structural repairs. By taking time to learn core principles of drain repair and installation—such as how to size pipes correctly, how to maintain cleanouts, and how to test your work—you can significantly extend the life of your plumbing system, protect your home, and avoid emergency calls in the middle of the night.

Understand How Your Drains Work

Effective drain repair starts with understanding the basic layout and logic of your home’s drainage system. Every fixture—sinks, tubs, showers, toilets, laundry machines—connects to a network of drain pipes that ultimately leads to a main sewer line or septic system. These pipes are not random; they are sized and sloped according to plumbing codes so that gravity can do the work. When you open a wall or crawl under a house to work on a drain, you are stepping into a system designed to move water and waste efficiently in one direction, with as few disruptions as possible.

Another key concept is venting. Many homeowners focus only on the drains they can see, like the P-trap under the sink, but every drain also needs adequate air supply through vents. Vents prevent suction from forming in the pipes, which would otherwise slow drainage and suck water out of traps, allowing sewer gases into your home. When replacing or rerouting drain lines, ignoring vent connections can lead to slow drains, gurgling sounds, and bad odors. Proper venting is one of the most overlooked, yet essential, pieces of the drain puzzle.

Cleanouts are another feature you should learn to identify before tackling repairs. A cleanout is an access point that allows you or a plumber to run a snake or inspection camera into the system. If you are planning any drain installation or replacement, think about how future maintenance will be done. Adding or preserving cleanouts at strategic points—near changes in direction, at the base of vertical stacks, and before the line exits the house—can save enormous time and money when clogs occur later on.

Finally, understand that all drains are interconnected. A clog in one branch can affect fixtures that seem unrelated. A problem in the main line might show up as a toilet that bubbles when you run the washing machine. When you approach a repair, look beyond the immediate leak or blockage and consider what is happening upstream and downstream. This big-picture view helps you avoid patching a symptom while ignoring the real cause.

Diagnose Before You Demolish

One of the worst mistakes in drain repair is tearing out pipes before you know exactly what is wrong. Before you cut anything, take time to diagnose carefully. Start with simple observations: Which fixtures are affected? Does the problem occur all the time or only when multiple fixtures are running? Do you notice gurgling sounds, foul odors, or slow drainage? These clues can help you determine whether you are dealing with a local issue, such as a hair clog in a shower, or a systemic problem, like a partially blocked main line.

Use basic tools before resorting to major demolition. A quality plunger, a hand auger (drain snake), and an enzyme-based drain cleaner (not harsh chemicals) can solve many minor issues. For deeper or recurring problems, renting an inspection camera can be a wise move. By feeding the camera through a cleanout or removed trap, you can visually inspect the inside of pipes, identify breaks, root intrusion, or accumulated buildup, and see exactly where repairs are needed. This targeted approach reduces unnecessary cutting into walls or floors.

Pay attention to patterns over time. If you have recurring clogs in the same location, it might indicate a sagging pipe (a “belly”), improper slope, or a fitting that was installed incorrectly. Keep a simple log of when problems occur and what you were doing at the time—such as running the dishwasher, flushing certain toilets, or doing laundry. This information is incredibly useful when planning repairs or speaking with a professional, and it prevents guesswork that can lead to costly missteps.

Lastly, don’t ignore warning signs just because water is still moving. Slow drains, occasional backups that “fix themselves,” or intermittent odors usually mean something is going wrong inside the system. Acting early, when the issue is still small, often means you can handle it with minimal repair work instead of a full-scale replacement later. Treat diagnosis as a critical phase, not a formality.

Choose The Right Materials

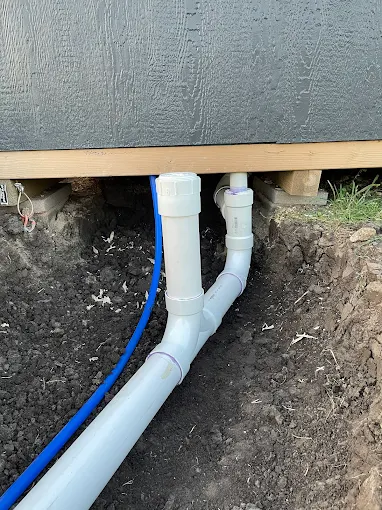

When it is time to repair or install new drain lines, your choice of materials has long-term consequences for performance and durability. Modern homes often use PVC or ABS plastic for drain, waste, and vent (DWV) systems. These materials are lightweight, resistant to corrosion, and relatively easy for homeowners to work with. However, you must match existing materials correctly: for example, connecting PVC to cast iron or clay requires specific transition couplings rated for that purpose, not just any rubber sleeve or improvised connector.

If your home has older cast iron or galvanized steel drains, you will need to decide whether to patch specific sections or plan for staged replacement. Cast iron is durable but can corrode from the inside, narrowing the pipe and causing chronic clogs. When you cut into cast iron, use proper safety gear and tools designed for metal, and be prepared to support the remaining pipe so its weight does not stress joints. When connecting new plastic sections, use shielded couplings with metal bands to ensure a secure, code-compliant joint.

Pipe sizing is another critical detail that many homeowners overlook. A bathroom sink typically uses 1 1/4″ or 1 1/2″ trap and drain, showers and tubs usually run 1 1/2″ or 2″, and toilets need a 3″ or 4″ line. The main building drain is usually 4″. Installing a drain that is too small can cause frequent blockages; installing one that is too large without proper slope can cause solids to settle rather than wash away. Always follow local code requirements for sizing and fixture unit calculations, and when in doubt, match or slightly upgrade the existing size rather than downsizing.

Do not forget about fittings and sealants. Use the correct fittings—sanitary tees, wyes, long-sweep elbows—specifically designed for drainage, not pressure water lines. For plastic pipes, use the proper primer and solvent cement, and follow the drying times. For threaded metal connections, use thread sealant or tape rated for the application. Cutting corners on these small details can lead to leaks inside walls and floors that remain hidden until significant damage has occurred.

Install With Slope, Support, And Access

Proper installation is not just about connecting point A to point B; it is about how the pipe runs between those points. The slope of horizontal drain lines is one of the most important factors for performance. In most residential systems, a slope of about 1/4 inch per foot is standard for small-diameter pipes. Too little slope and waste will not move effectively; too much slope and water can outrun solids, leaving debris behind to form clogs. Use a level and measure carefully along the entire run, adjusting hangers or supports as needed.

Support is equally critical, especially for plastic pipes that can sag over time if not adequately strapped. Use approved hangers and straps, and follow spacing guidelines—typically every few feet for horizontal runs, and at key points near fittings and transitions. In crawl spaces or basements, check that pipes are not resting on sharp edges, subject to movement, or exposed to physical damage. A well-supported drain line maintains its slope, resists vibration, and is less likely to crack or separate at joints.

When planning your route, minimize sharp turns and unnecessary fittings. Every 90-degree bend increases the risk of clogs and makes future cleaning more difficult. Where you must change direction, consider using two 45-degree fittings or a long-sweep elbow to create a gentler curve. Think like a maintenance technician: could a drain snake or camera pass through this section easily in the future? If the answer is no, adjust your layout to make access simpler.

Finally, always plan for cleanouts and access points during installation. It is far easier and cheaper to add a cleanout while installing new pipe than to cut into a finished wall or slab later. Place cleanouts near where a horizontal line leaves the house, at the base of vertical stacks, and at long runs with multiple turns. This forward-thinking approach transforms a simple repair into a long-term upgrade for your entire system.

Know When To DIY And When To Call A Pro

Not every drain repair is a good candidate for DIY. Replacing a trap under a sink, installing a new tailpiece, or clearing a straightforward clog with a hand snake are within the reach of many homeowners, provided they work carefully and follow instructions. These projects are excellent opportunities to learn how your system works and to save money. Take your time, lay out parts before disassembly, and keep towels and a bucket handy to catch residual water when you open the system.

However, once you move into structural work—cutting into main lines, working inside walls or ceilings, or altering vent and drain configurations—the risk increases. Mistakes can lead to hidden leaks, code violations, or even health hazards from sewer gases or contaminated water. If a repair involves the main sewer line, repeated backups affecting multiple fixtures, or any work that requires breaking concrete, it is usually wise to involve a licensed plumber. Professionals have specialized equipment such as power augers, hydro-jetting machines, and inspection cameras that can handle issues more safely and efficiently.

Permits and inspections are another factor. Many jurisdictions require permits for significant drain alterations, especially when modifying main lines, adding bathrooms, or relocating fixtures. A professional will understand local codes and can ensure that your installation passes inspection, which is important for safety and also for future home resale. If you are unsure whether a permit is needed, a quick call to your local building department or a trusted plumber can clarify the requirements.

Even if you prefer to tackle some work yourself, consider a hybrid approach. You might perform basic demolition, access, or cleanup while leaving critical connections, vent planning, or main tie-ins to a pro. This cooperative method can reduce costs while still ensuring that the most sensitive parts of the job are done correctly. For more information on professional services and local requirements, you can refer to resources like null for guidance.

Test, Inspect, And Maintain

Once you complete a drain repair or new installation, resist the urge to close everything up immediately. Thorough testing is the final, non-negotiable step. Start by running water at low flow to check for obvious leaks at joints, traps, and connections. Gradually increase the flow, and run multiple fixtures at the same time if they share a drain branch. Observe how quickly water drains, listen for gurgling, and check for any signs of moisture along the pipe runs, especially at newly installed sections.

For larger projects, such as replacing a section of main line or installing new branches, a more formal test is recommended. This might involve temporarily plugging the line and filling it with water to a certain height (a water test) and then monitoring for pressure loss or visible leaks. Some professionals use air tests under controlled conditions. While homeowners may not have all the specialized tools, you can still perform a version of this by filling tubs and sinks and then draining them simultaneously to stress the system.

Visual inspection is also important, particularly in accessible areas like basements, crawl spaces, and unfinished walls. Use a bright flashlight to check all joints, hangers, and supports. Look for any signs of sweating, dripping, or movement when fixtures are in use. If you have access to an inspection camera, consider a quick pass through critical sections to confirm there are no internal obstructions or misaligned joints that could become problems later.

After the initial testing, ongoing maintenance will protect your work. Avoid pouring grease, coffee grounds, or large food particles down kitchen drains. Use hair catchers in showers and tubs. Periodically flush drains with hot water and, where appropriate, safe enzyme-based cleaners that break down organic buildup. Address small issues—like occasional slow drains or minor odors—promptly before they escalate. By combining careful installation with sensible maintenance, you can keep your drains functioning smoothly for many years.

Frequently Asked Questions

How do I know if my drain problem is in the main line or just one fixture? If only one fixture, such as a single sink or shower, is draining slowly or backing up, the issue is usually local to that fixture’s trap or immediate branch line. Try clearing the trap, using a hand snake, or cleaning hair and debris from the stopper area. If multiple fixtures in the same area are affected—especially if toilets bubble when other fixtures drain or if lower-level fixtures back up—the problem is more likely in a shared branch or the main sewer line. In that case, check any accessible cleanouts and consider using a longer drain snake or calling a professional to inspect the main line.

What slope should I use when installing new drain pipes? For most residential drain lines up to 3 inches in diameter, a slope of about 1/4 inch per foot is recommended and often required by code. Larger pipes may use 1/8 inch per foot, depending on local regulations. Too little slope causes slow drainage and frequent clogs, while too much slope can cause water to outrun solids. Use a level and measuring tape to ensure consistent slope along the entire run, adjusting hangers and supports as you go. Always confirm local code requirements before finalizing your installation.

Can I mix different types of pipe materials in my drain system? Yes, you can transition between materials such as cast iron and PVC or ABS, but you must use the correct transition fittings. These are typically shielded rubber couplings with metal bands designed for specific material combinations and sizes. Do not use unshielded couplings or makeshift adapters, as they may not provide a secure, long-lasting seal and could violate plumbing codes. When in doubt, bring a sample of your existing pipe to a plumbing supply store and ask for a compatible, code-approved transition fitting.

Is chemical drain cleaner safe to use before doing repairs? Many harsh chemical drain cleaners can damage older pipes, especially metal ones, and create a safety hazard for anyone working on the system afterward. If you plan to open pipes, cut sections, or handle traps, it is safer to avoid caustic chemical cleaners. Instead, use mechanical methods such as plungers, hand snakes, or enzyme-based cleaners that are gentler on pipes and safer for you. If chemicals have already been used, wear gloves and eye protection, and flush the system thoroughly with water before beginning any repair work.

When should I call a professional instead of doing drain repairs myself? Call a professional if you are dealing with repeated backups affecting multiple fixtures, suspected main line issues, sewage odors you cannot trace, or any repair that involves cutting into structural elements or concrete. You should also involve a licensed plumber when adding new bathrooms, relocating major fixtures, or altering vent configurations, as these projects often require permits and inspections. If at any point you feel uncertain about safety, code compliance, or the complexity of the work, it is better to get expert help than to risk hidden damage or future failures.